Add to Cart

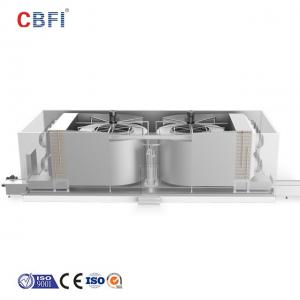

China Factory Direct Sale IQF Customizable Laminated Spiral Quick Freezer Frozen Meat Production Line

IQF (Individual Quick Freezing) technology is a cutting-edge technology for the food industry that enables rapid freezing of food products without the formation of ice crystals. This technology has revolutionized the way food products are frozen, and the IQF freezer is now considered one of the must-have equipment for food producers. The IQF freezer utilizes a horizontal airflow technology that ensures the food products remain separated during the freezing process, resulting in better product quality, texture, and taste.

Features

The IQF customizable stacked spiral freezing machine for meat processing lines comes with a variety of features that make it ideal for this type of application. Some of the features include:

| Customizable design | The IQF freezer can be customized to meet specific customer requirements with regard to capacity, footprint, and freezing temperature. |

| Multiple belts | The IQF freezer uses multiple conveyor belts that facilitate high product throughput and also enhance production efficiency. |

| Spiral design | The spiral design of the freezer ensures that the products are evenly exposed to the refrigerated air, resulting in an even freeze. |

| Hygienic design | The freezer is designed to meet high food safety standards, with features such as easily removable belts and rollers that facilitate easy cleaning and sanitization. |

| Modular design | The modular design means that the freezer can be easily transported and assembled on site, reducing downtime during installation. |

Advantages

The IQF customizable stacked spiral freezing machine for meat processing lines offers a myriad of advantages for food producers including:

1. Improved product quality: The IQF freezer ensures that each food product is frozen separately, resulting in a product that retains its original shape, color, texture, and flavor.

2. Faster freezing times: The IQF freezer utilizes rapid cooling technology, resulting in shorter freezing times than traditional methods. This is ideal for meat processing lines where fast freezing times are essential.

3. Higher capacity: The IQF freezer can accommodate a higher capacity of food products compared to traditional freezers, resulting in higher production output.

4. Reduced labor costs: The IQF freezer requires minimal labor input, and the conveyor system is low maintenance, resulting in reduced labor costs for food producers.

5. Energy efficient: The IQF freezer is designed to be energy efficient, resulting in reduced running costs for food producers.

Requirements for Conveyor

The IQF freezer requires a specialized conveyor belt that is designed to meet certain requirements. Some of these requirements include:

1. Open mesh: The conveyor belt should have an open mesh design that allows for effective airflow, ensuring that each food product is exposed to the refrigerated air during the freezing process.

2. Non-stick surface: The conveyor belt should have a non-stick surface that prevents food products from sticking and also allows for easy cleaning and sanitization.

3. Durability: The conveyor belt should be made of high-quality materials that can withstand the harsh conditions of a freezer environment, such as low temperatures and moisture.

4. Non-toxic: The conveyor belt should be made of non-toxic materials that are safe for use in the food industry.

The IQF customizable stacked spiral freezing machine for meat processing lines is a game-changer in the food industry. It offers food producers a range of benefits, including improved product quality, faster freezing times, higher capacity, reduced labor costs, and energy efficiency. To ensure optimal performance, the IQF freezer requires a specialized conveyor belt that meets certain requirements, such as an open mesh design, non-stick surface, durability, and non-toxicity. As competition in the food industry continues to intensify, adopting cutting-edge technology such as the IQF freezer is crucial for food producers looking to stay ahead.